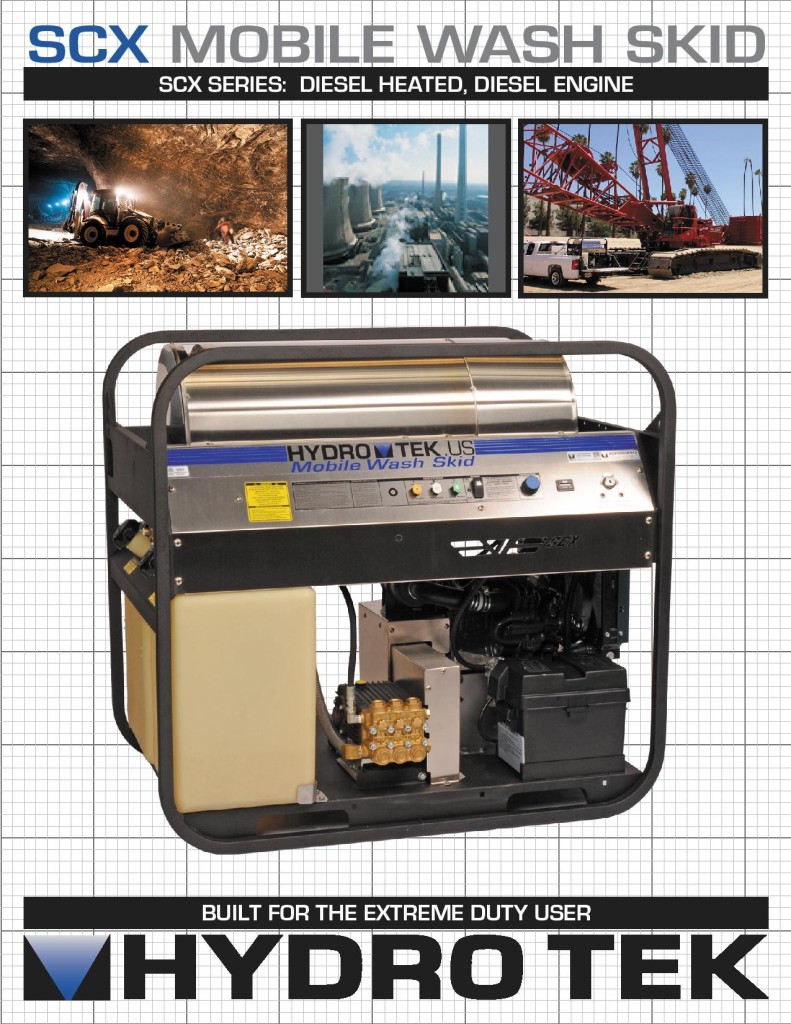

Description

The SC-X Series Hot Water Pressure Washers are self-contained Mobile Wash Skids designed with the extreme duty user in mind and includes extra features to make it suitable for use in harsh and remote environments. The SC-X is designed for extra duty industrial use. It is self-contained and requires no outside power. It utilizes larger gasoline or diesel engines and pumps than our “SC” and “SS” series washers for tackling the biggest jobs with higher water volume. High pressure, hot water spray is generated on demand by the diesel fired burner so you can achieve the best cleaning results on grease and grime anywhere your job requires.

Features:

Rugged Pro-Tect-It™ Frame:

An extra-large, rugged, powder-coated steel frame surrounds the entire machine protecting its vital components. This Pro-Tect-It chassis has 4-way forklift access as well as built in lifting eyes so the machine can be top lifted with a harness or crane and the eyes double as tie down points for safe transportation. Each frame has double wall steel engine mounts to absorb engine vibration for smooth performance and includes mounting holes to hold optional stainless hose reels.

Stainless Steel Panels:

The stainless panels and coil wrap offer lifetime rust resistance and protection while keeping your machine looking new for years to come. (Optional stainless frame and enclosure panels available)

High Output 12v Diesel Heating System:

The 12v burner uses dependable PowerLight technology for maximum burner performance and efficiency, heating quickly, up to 250°F, to efficiently clean extra tough grime. No outside power source needed.

SpiraLast™ Coil:

The coil is a Hydro Tek manufactured SpiraLast™ heating coil. Robotically fused ½” schedule 80 steel pipe is cold rolled to protect the steel pipe from fatigue and the spiral coil is then surrounded by ceramic insulation and stainless enclosure with double-wall end caps. Check out our Lifetime Coil Warranty.

High Output Industrial Engines:

Heavy duty, multi cylinder diesel engines are water cooled and include oil filtration and electric key start. A side mount muffler prevents water ingress and reduces engine vibration. Panel mounted engine condition indicator lights to monitor your engine temperature & oil pressure.

Belt Driven Pump:

High torque, V-belt driven pump, low RPM, cooler and quieter operation for continuous duty performance. EZ Align™ belt tensioning system allows for easy, single bolt, belt tensioning adjustments.

Extra Large Fuel Capacity, 36 gallons:

Heavy duty, “roto-molded”, rust free fuel tanks with frame mounted, water separating fuel filter to protect against contaminated fuel. Large fuel tanks extend run time, eliminating interruptions to refuel.

More Standard Features:

Burst disc technology, pressure and flow switches, high limit thermostat, and pressure relief valve for operator safety Adjustable thermostat up to 250ºF, hour meter, and lighted on/off switches are panel mounted for easy operator access.

Heavy duty gun and wand with nozzle storage, heavy duty 50’ hose, quick release nozzle set, snap close battery box.

High flow models are two-gun compatible. Simply add the two-gun kit option to use with two operators to get your job done faster

Mine Specifications: Additional features for SCX30005-MS: 8 gallon float tank with low water shutdown, GeniSys flame-out safety control system for the burner, locking battery isolator switch, extended stainless front panel, emergency stop button, stainless drip/drain pan, total relief unloader. Pump, engine, drive & heater coil are operated 25% less than max. ratings for prolonged life.

Oil & Gas Drilling Specifications: Additional features for SCX30006-OS Hammerhead: Stainless steel frame, emergency air choke shutdown, stainless drip/drain pan

Specifications

| Model | PSI | GPM | Temp. | CC | Engine |

| SCX30008D12 | 3000 | 7.8 | 250 F | 719 | Kubota Diesel |

| SCX35005D12 | 3500 | 4.7 | 250 F | 599 | Kubota Diesel |

| SCX35006D12 | 3500 | 5.5 | 250 F | 599 | Kubota Diesel |

Dimensions: 51.5″l x 32.5″w 47″h

Hydro Tek Parts Breakdown and Exploded Views 2015

SM Series: Compact, Portable, Gas Powered, Diesel Heated

SM Series: Compact, Portable, Gas Powered, Diesel Heated SS Series: Mobile Wash Skids - Compact, Gas Powered, Diesel Heated

SS Series: Mobile Wash Skids - Compact, Gas Powered, Diesel Heated SC Series: Mobile Wash Skids - Self-Contained, Gas Powered, Diesel Heated

SC Series: Mobile Wash Skids - Self-Contained, Gas Powered, Diesel Heated SC-X Series : Diesel Powered, Diesel Heated for Extreme Duty

SC-X Series : Diesel Powered, Diesel Heated for Extreme Duty HD Series: Compact, Portable, Electric Powered, Diesel Heated

HD Series: Compact, Portable, Electric Powered, Diesel Heated HP Series: Hot Water Pressure Washer - Portable Electric, Diesel Heated with Exceptional Heat Output

HP Series: Hot Water Pressure Washer - Portable Electric, Diesel Heated with Exceptional Heat Output HN Series: Stationary, Electric Powered, Natural Gas, LP or Diesel Heated

HN Series: Stationary, Electric Powered, Natural Gas, LP or Diesel Heated CPS Series: Cold Water Pressure Washer

CPS Series: Cold Water Pressure Washer Pressure Washer Surface Cleaner - Hydro Twister®

Pressure Washer Surface Cleaner - Hydro Twister® Hydro Twister® Convertible Undercarriage Surface Cleaner

Hydro Twister® Convertible Undercarriage Surface Cleaner Pressure Washer Hose Reels

Pressure Washer Hose Reels Hot Link Hot Water Generator

Hot Link Hot Water Generator Muck Scupper & Sludge Pump

Muck Scupper & Sludge Pump High Reach Wash Pole

High Reach Wash Pole Completely Self Contained, Gas Powered Vacuum Recovery System

Completely Self Contained, Gas Powered Vacuum Recovery System Electric Powered Water Evacuation System with Pump Out

Electric Powered Water Evacuation System with Pump Out ProTowWash® Portable Commercial Pressure Washer Trailers

ProTowWash® Portable Commercial Pressure Washer Trailers Hydro Tek Tank Skid Mounted Pressure Washers

Hydro Tek Tank Skid Mounted Pressure Washers Tow & Stow Transporter

Tow & Stow Transporter Portable Recycle Systems for Truck or Trailer Mount

Portable Recycle Systems for Truck or Trailer Mount