Description

HD Series Hot Water Pressure Washer

Features:

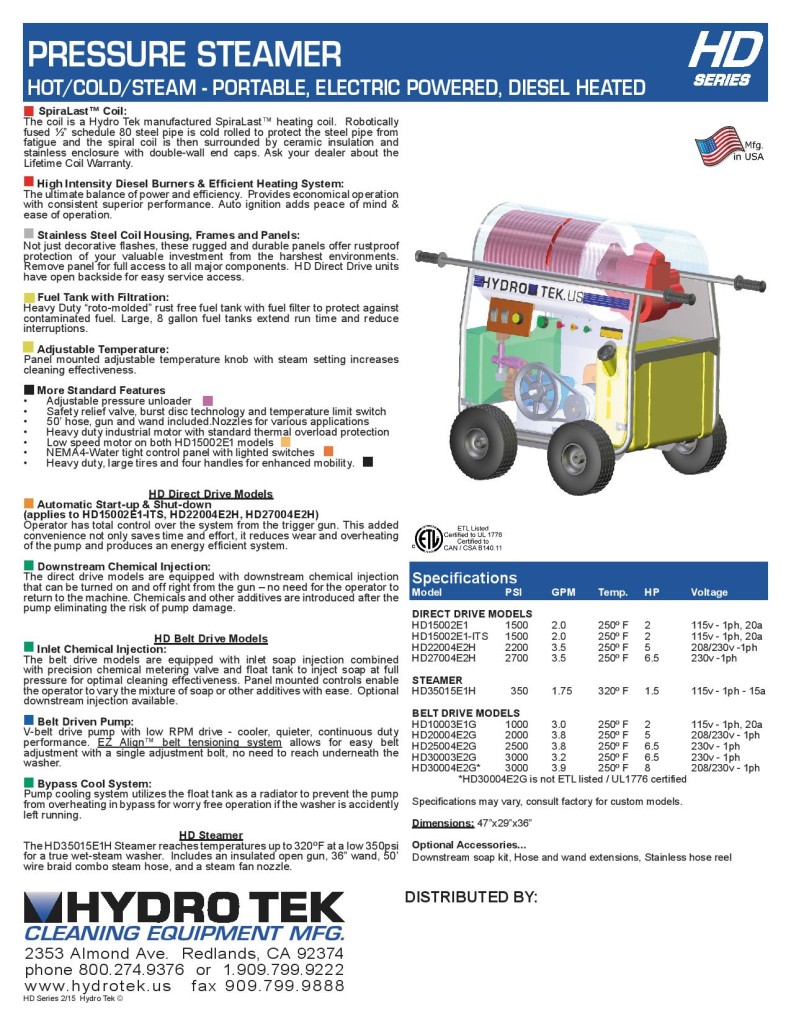

SpiraLast™ Coil:

The coil is a Hydro Tek manufactured SpiraLast™ heating coil. Robotically fused ½” schedule 80 steel pipe is cold rolled to protect the steel pipe from fatigue and the spiral coil is then surrounded by ceramic insulation and stainless enclosure with double-wall end caps. Ask your dealer about the Lifetime Coil Warranty.

High Intensity Diesel Burners & Efficient Heating System:

The ultimate balance of power and efficiency. Provides economical operation with consistent superior performance. Auto ignition adds peace of mind & ease of operation.

Stainless Steel Coil Housing, Frames and Panels:

Not just decorative flashes, these rugged and durable panels offer rustproof protection of your valuable investment from the harshest environments. Remove panel for full access to all major components. HD Direct Drive units have open backside for easy service access.

Fuel Tank with Filtration:

Heavy Duty “roto-molded” rust free fuel tanks with fuel filter to protect against contaminated fuel. Large fuel tanks extend run time and reduce interruptions.

Adjustable Temperature:

Panel mounted adjustable temperature knob with steam setting increases cleaning effectiveness.

More Standard Features

Adjustable pressure unloader

Safety relief valve, burst disc technology and temperature limit switch

50’ hose, gun and wand included.Nozzles for various applications

Heavy duty industrial motor with standard thermal overload protection

Low speed motor on both HD15002E1 models

NEMA4-Water tight control panel with lighted switches

Heavy duty, large tires and four handles for enhanced mobility.

HD Series Hot Water Pressure Washer Direct Drive Models

Automatic Start-up & Shut-down

(applies to HD15002E1-ITS, HD22004E2H, HD27004E2H)

Operator has total control over the system from the trigger gun. This added convenience not only saves time and effort, it reduces wear and overheating of the pump, prevents the pump from running dry and produces an energy efficient system.

Downstream Chemical Injection:

The direct drive models are equipped with downstream chemical injection that can be turned on and off right from the gun – no need for the operator to return to the machine. Chemicals and other additives are introduced after the pump eliminating the risk of pump damage.

HD Belt Drive Models

Inlet Chemical Injection:

The belt drive models are equipped with inlet soap injection combined with precision chemical metering valve and float tank to inject soap at full pressure for optimal cleaning effectiveness. Panel mounted controls enable the operator to vary the mixture of soap or other additives with ease. Optional downstream injection available.

Belt Driven Pump:

V-belt drive pump with low RPM drive – cooler, quieter, continuous duty performance. EZ Align™ belt tensioning system allows for easy belt adjustment with a single adjustment bolt, no need to reach underneath the washer.

Bypass Cool System:

Pump cooling system utilizes the float tank as a radiator to prevent the pump from overheating in bypass for worry free operation if the washer is accidently left running.

HD Steamer

The HD35015E1H Steamer reaches temperatures up to 320ºF at a low 350psi for a true wet-steam washer. Includes an insulated open gun, 36” wand, 50’ wire braid combo steam hose, and a steam fan nozzle.

Specifications

| Direct Drive Model | PSI | GPM | Temp | HP | Voltage |

| HD15002E1 | 1500 | 2 | 250 | 2 | 115v 1ph 20a |

| HD15002E1-ITS | 1500 | 2 | 250 | 2 | 115v 1ph 20a |

| HD22004E2H | 2200 | 3.5 | 250 | 5 | 280/230 1PH 24a |

| HD27004E2H | 2700 | 3.5 | 250 | 6.5 | 230v 1ph 27a |

| Steamer | PSI | GPM | Temp | HP | Voltage |

| HD35015E1H | 350 | 1.75 | 320º F | 1.5 | 115v – 1ph – 15a |

| Belt Drive Model | PSI | GPM | Temp | HP | Voltage |

| HD10003E1G | 1000 | 2.8 | 250 | 2 | 115v 1ph 20a |

| HD20004E2G | 2000 | 3.5 | 250 | 5 | 208/230v – 1ph 24amp |

| HD25004E2G | 2500 | 3.6 | 250 | 6.5 | 230v – 1ph 27amp |

| HD30003E2G | 3000 | 3.2 | 250 | 6.5 | 230v – 1ph 27amp |

| HD30004E2G | 3000 | 3.9 | 250 | 8 | 208/230v – 1ph 36amp |

Specifications may vary, consult factory for custom models

Dimensions: 17″l x 29″w x 36″h

SM Series: Compact, Portable, Gas Powered, Diesel Heated

SM Series: Compact, Portable, Gas Powered, Diesel Heated SS Series: Mobile Wash Skids - Compact, Gas Powered, Diesel Heated

SS Series: Mobile Wash Skids - Compact, Gas Powered, Diesel Heated SC Series: Mobile Wash Skids - Self-Contained, Gas Powered, Diesel Heated

SC Series: Mobile Wash Skids - Self-Contained, Gas Powered, Diesel Heated SC-X Series : Diesel Powered, Diesel Heated for Extreme Duty

SC-X Series : Diesel Powered, Diesel Heated for Extreme Duty HD Series: Compact, Portable, Electric Powered, Diesel Heated

HD Series: Compact, Portable, Electric Powered, Diesel Heated HP Series: Hot Water Pressure Washer - Portable Electric, Diesel Heated with Exceptional Heat Output

HP Series: Hot Water Pressure Washer - Portable Electric, Diesel Heated with Exceptional Heat Output HN Series: Stationary, Electric Powered, Natural Gas, LP or Diesel Heated

HN Series: Stationary, Electric Powered, Natural Gas, LP or Diesel Heated CPS Series: Cold Water Pressure Washer

CPS Series: Cold Water Pressure Washer Pressure Washer Surface Cleaner - Hydro Twister®

Pressure Washer Surface Cleaner - Hydro Twister® Hydro Twister® Convertible Undercarriage Surface Cleaner

Hydro Twister® Convertible Undercarriage Surface Cleaner Pressure Washer Hose Reels

Pressure Washer Hose Reels Hot Link Hot Water Generator

Hot Link Hot Water Generator Muck Scupper & Sludge Pump

Muck Scupper & Sludge Pump High Reach Wash Pole

High Reach Wash Pole Completely Self Contained, Gas Powered Vacuum Recovery System

Completely Self Contained, Gas Powered Vacuum Recovery System Electric Powered Water Evacuation System with Pump Out

Electric Powered Water Evacuation System with Pump Out ProTowWash® Portable Commercial Pressure Washer Trailers

ProTowWash® Portable Commercial Pressure Washer Trailers Hydro Tek Tank Skid Mounted Pressure Washers

Hydro Tek Tank Skid Mounted Pressure Washers Tow & Stow Transporter

Tow & Stow Transporter Portable Recycle Systems for Truck or Trailer Mount

Portable Recycle Systems for Truck or Trailer Mount