Description

Hydro Tek Hose Reels can be mounted anywhere providing convenient and quick storage of both discharge and inlet hoses for your pressure washer. These pressure washer hose reels have the ability to swivel 180° allowing you to unroll the hose from any direction. When you are ready to travel simply reel the hose on to the drum with the provided handle, set the lock pin, and you’re ready to go.

Base Mount Hose Reels

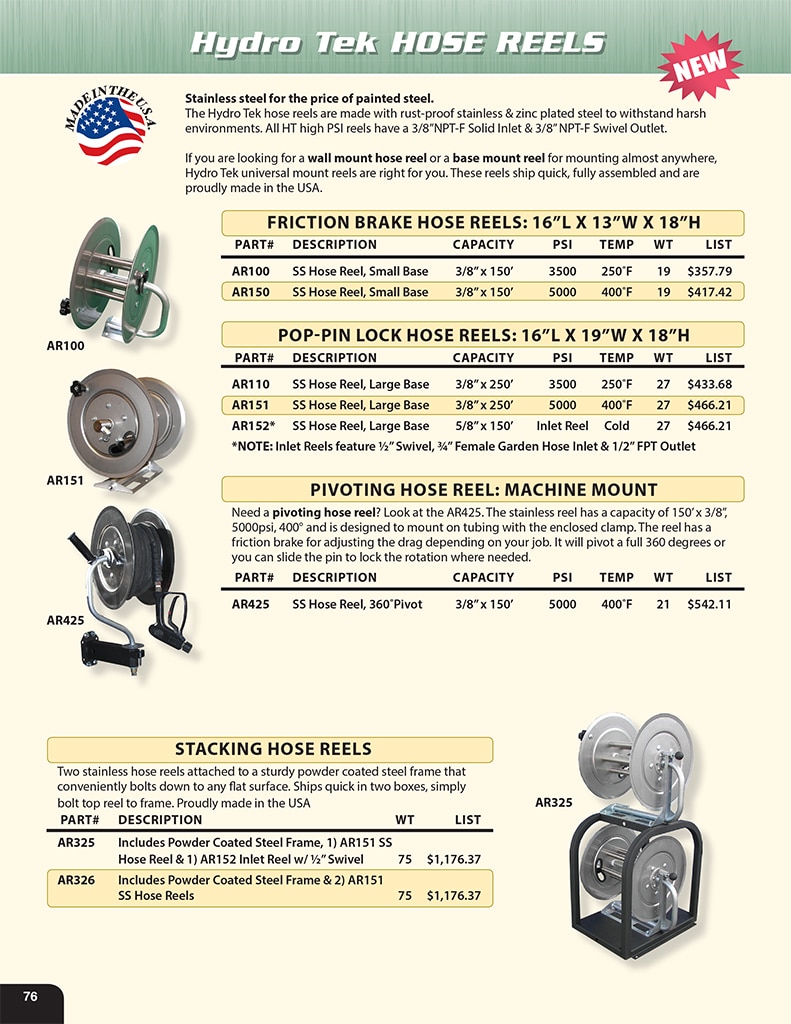

If you are looking for a wall mount hose reel or a base mount reel for mounting almost anywhere, Hydro Tek universal mount hose reels are right for you. These hose reels are shipped fully assembled, ship quickly, and are proudly made in the USA.

AR100 |

AR151 |

AR188 |

Need a pivoting hose reel?

Look at the AR425. The stainless reel has a capacity of 150’ x 3/8”, 5000psi, 400° and is designed to mount on tubing with the enclosed clamp, or can be mounted on a wall. The reel has a friction brake for adjusting the drag depending on your job. It will pivot a full 360 degrees or you can slide the pin to lock the rotation where needed.

Ships quickly, fully assembled, & is made in the USA

Stacking Hose Reels

Two stainless hose reels attached to a sturdy powder coated steel frame that conveniently bolts down to any flat surface.

Two configurations to choose from:

Part# AR325 has reel capacities of 250’ x 3/8”, 5000psi, 400° paired with a 150’ inlet reel.

Part# AR326 has reel capacities of 250’ x 3/8”, 5000psi, 400° paired with another of the same.

Ships quickly in 2 separate boxes, Made in the USA

Specifications

| Part # | Temp. | Capacity | PSI | Type |

| AR100 | 250°F | 150’ of ⅜” | 3500 | narrow-base mount, friction brake |

| AR150 | 400°F | 150’ of ⅜” | 5000 | narrow-base mount, friction brake |

| AR110 | 250°F | 250’ of ⅜” | 3500 | large-base mount, pop-pin brake |

| AR151 | 400°F | 250’ of ⅜” | 5000 | large-base mount, pop-pin brake |

| AR152 | cold | 150’ of ⅝” | inlet | large-base mount, pop-pin brake |

| AR188 | 400°F | 100’ of ⅜” | 5000 | wall mount to 16” stud width |

SM Series: Compact, Portable, Gas Powered, Diesel Heated

SM Series: Compact, Portable, Gas Powered, Diesel Heated SS Series: Mobile Wash Skids - Compact, Gas Powered, Diesel Heated

SS Series: Mobile Wash Skids - Compact, Gas Powered, Diesel Heated SC Series: Mobile Wash Skids - Self-Contained, Gas Powered, Diesel Heated

SC Series: Mobile Wash Skids - Self-Contained, Gas Powered, Diesel Heated SC-X Series : Diesel Powered, Diesel Heated for Extreme Duty

SC-X Series : Diesel Powered, Diesel Heated for Extreme Duty HD Series: Compact, Portable, Electric Powered, Diesel Heated

HD Series: Compact, Portable, Electric Powered, Diesel Heated HP Series: Hot Water Pressure Washer - Portable Electric, Diesel Heated with Exceptional Heat Output

HP Series: Hot Water Pressure Washer - Portable Electric, Diesel Heated with Exceptional Heat Output HN Series: Stationary, Electric Powered, Natural Gas, LP or Diesel Heated

HN Series: Stationary, Electric Powered, Natural Gas, LP or Diesel Heated CPS Series: Cold Water Pressure Washer

CPS Series: Cold Water Pressure Washer Pressure Washer Surface Cleaner - Hydro Twister®

Pressure Washer Surface Cleaner - Hydro Twister® Hydro Twister® Convertible Undercarriage Surface Cleaner

Hydro Twister® Convertible Undercarriage Surface Cleaner Pressure Washer Hose Reels

Pressure Washer Hose Reels Hot Link Hot Water Generator

Hot Link Hot Water Generator Muck Scupper & Sludge Pump

Muck Scupper & Sludge Pump High Reach Wash Pole

High Reach Wash Pole Completely Self Contained, Gas Powered Vacuum Recovery System

Completely Self Contained, Gas Powered Vacuum Recovery System Electric Powered Water Evacuation System with Pump Out

Electric Powered Water Evacuation System with Pump Out ProTowWash® Portable Commercial Pressure Washer Trailers

ProTowWash® Portable Commercial Pressure Washer Trailers Hydro Tek Tank Skid Mounted Pressure Washers

Hydro Tek Tank Skid Mounted Pressure Washers Tow & Stow Transporter

Tow & Stow Transporter Portable Recycle Systems for Truck or Trailer Mount

Portable Recycle Systems for Truck or Trailer Mount